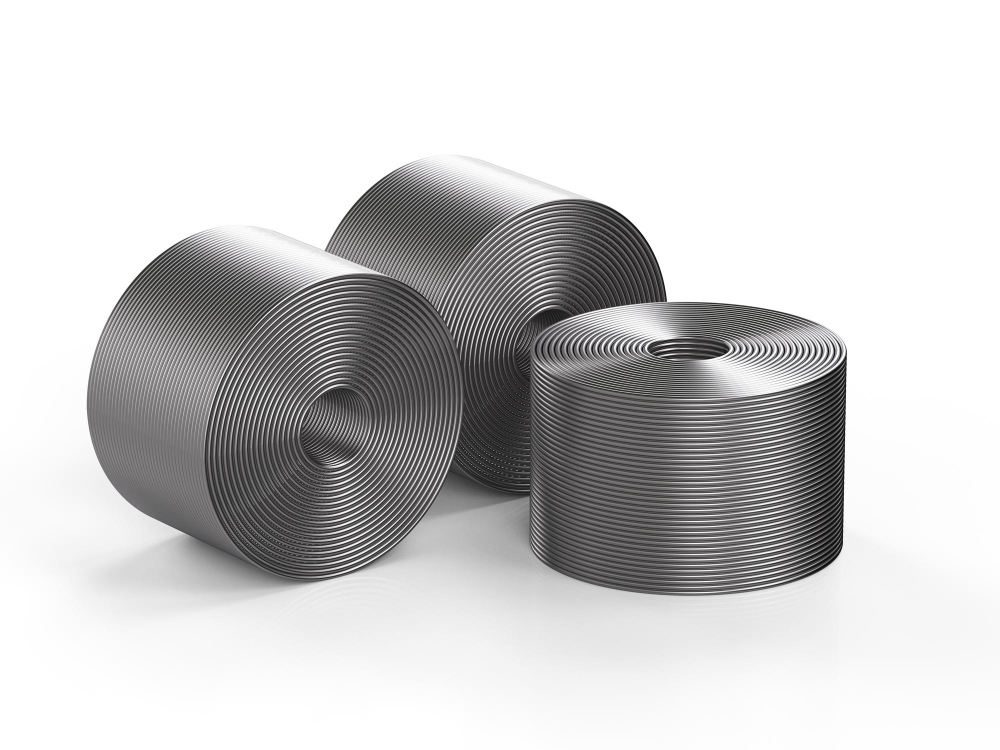

Galvanized flat steels are obtained by undergoing processes such as continuous annealing, galvanizing (zinc) coating and optional passivation or lubrication after the surface cleaning process of Cold rolled Fullhard (FH) products. Although galvanized steels have a much higher corrosion resistance than other steel products, they can also be painted according to the usage area. Coated products can be supplied in the range of Z60 – Z600. General usage areas are Automotive, Automotive Sub-Industry, White Goods, White Goods Sub-Industry, Construction and building sectors.

Grades:

Steels Suitable for Cold Forming: DX51D+Z – DX52D+Z – DX53D+Z – DX54D+Z – DX56D+Z – DX57D+Z

Dual Phase Steels: DP450, DP500, DP600, DP800

High Strength Low Alloy Steels: HX260LAD, HX300LAD, HX340LAD, HX380LAD, HX420LAD, HX500LAD

Kiln-Hardenable Steels: HX180BD, HX220BD, HX260BD, HX300BD

High Strength Rephosphorized Steels: HX180YD, HX220YD, HX260YD, HX300YD

Non-Alloy Structural Steels: S220 GD+Z, S250 GD+Z, S280 GD+Z, S320 GD+Z, S350 GD+Z, S390 GD+Z, S420GD+Z, S450GD+Z, S550GD+Z